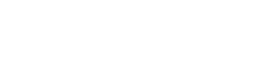

This project began with the idea of building a desktop PC from wood.

A Japanese theme seemed very fitting with this build.

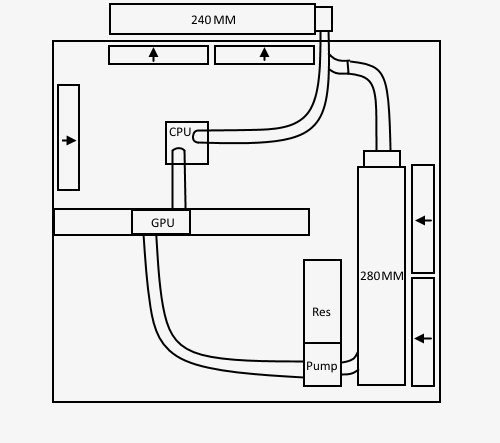

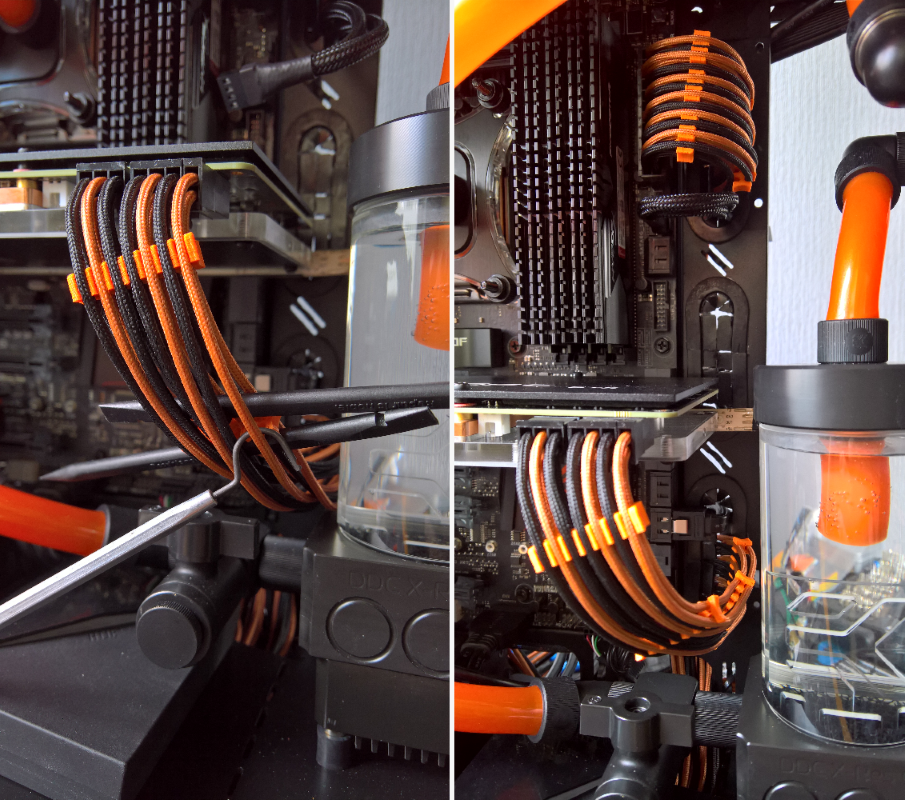

The main goal was to create a PC that was clean and as quiet as possible. That’s why it has no hard drives, but only SSD’s.

The large number of fans isn’t really necessary in terms of cooling capacity, but allows running them all at very low RPM’s, to keep it quiet.

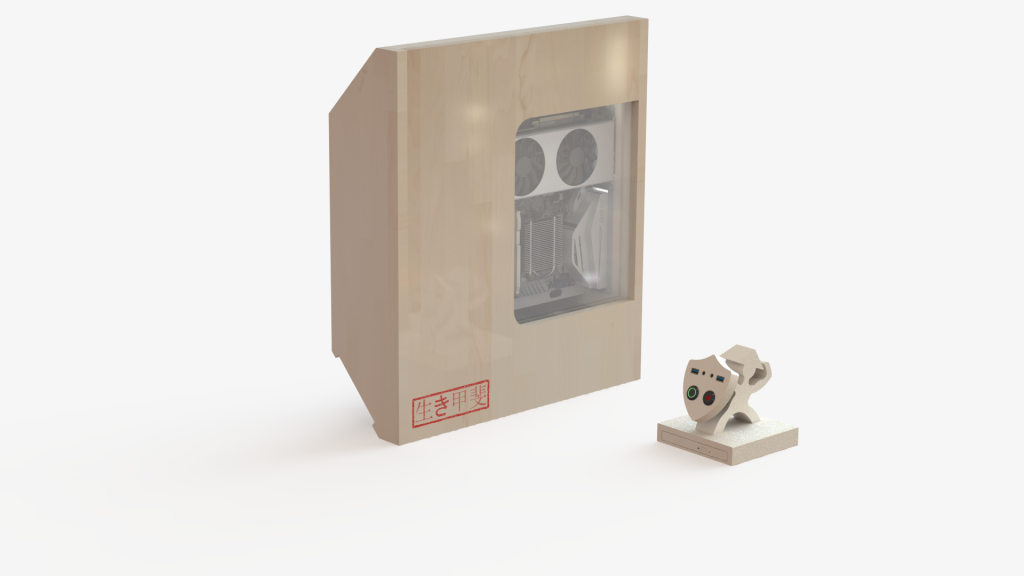

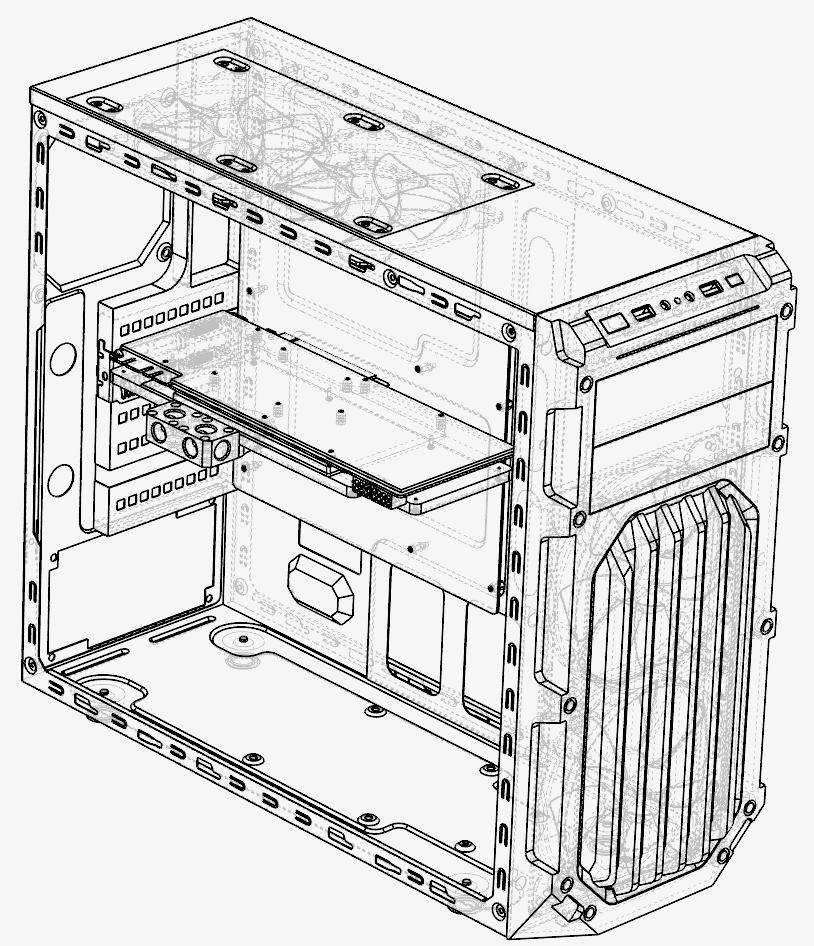

To get the case itself to be as clean as possible, every possible connector or button was removed. This added the challenge of housing them externally.

This was done by designing a Japanese figure, which is standing on top of the external DVD player.

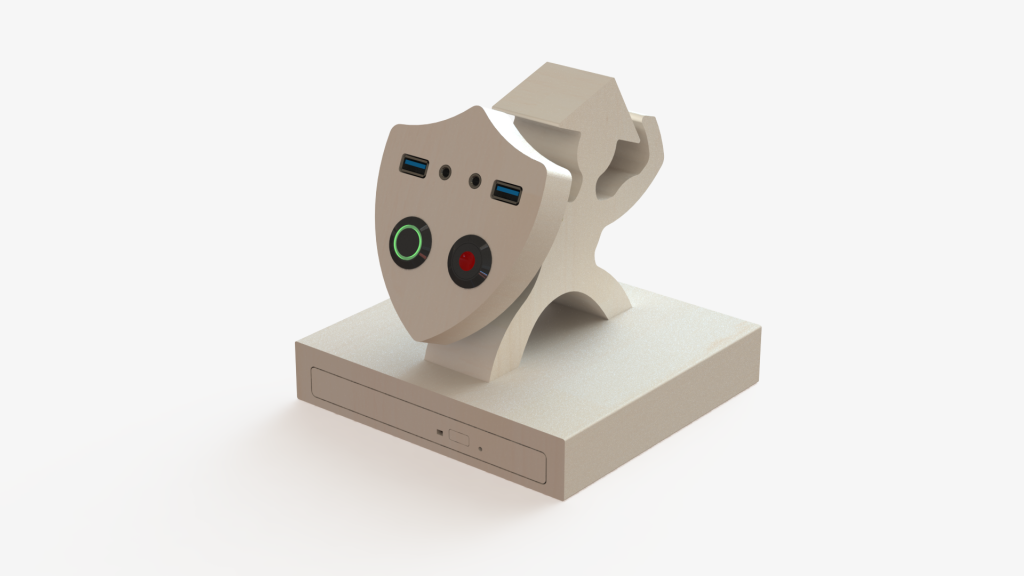

Below is shown how I designed the inside of the figure in a way that all the cables would fit.

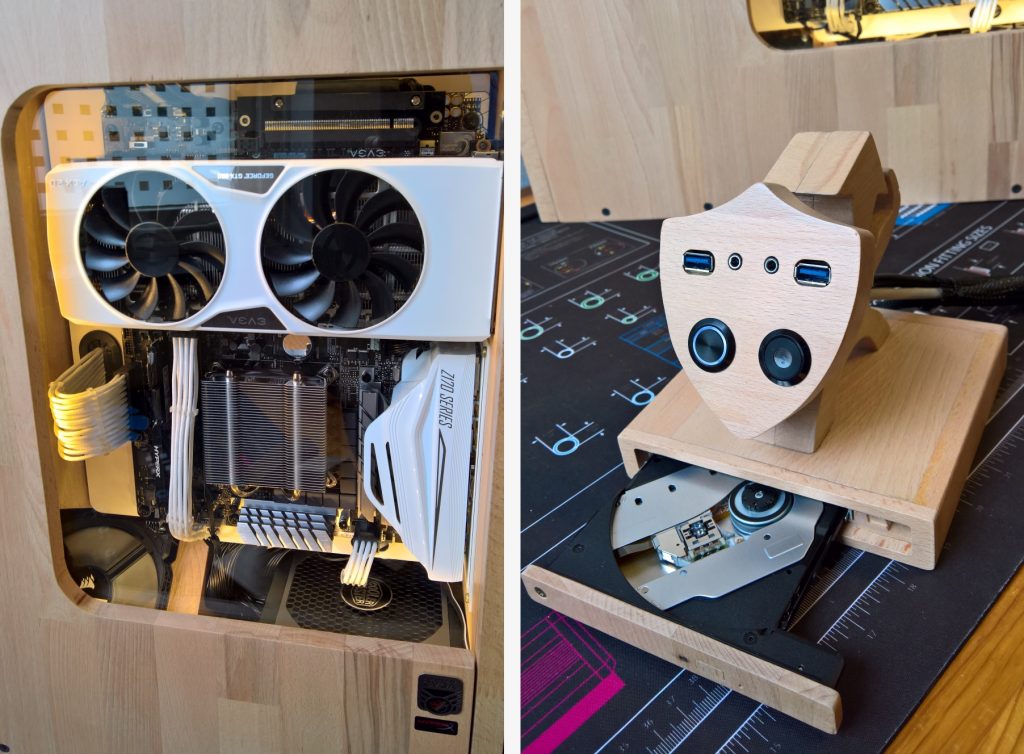

Lots of parts were designed and custom made, but other of the shelf parts, were modified, like the GPU cooler for instance.

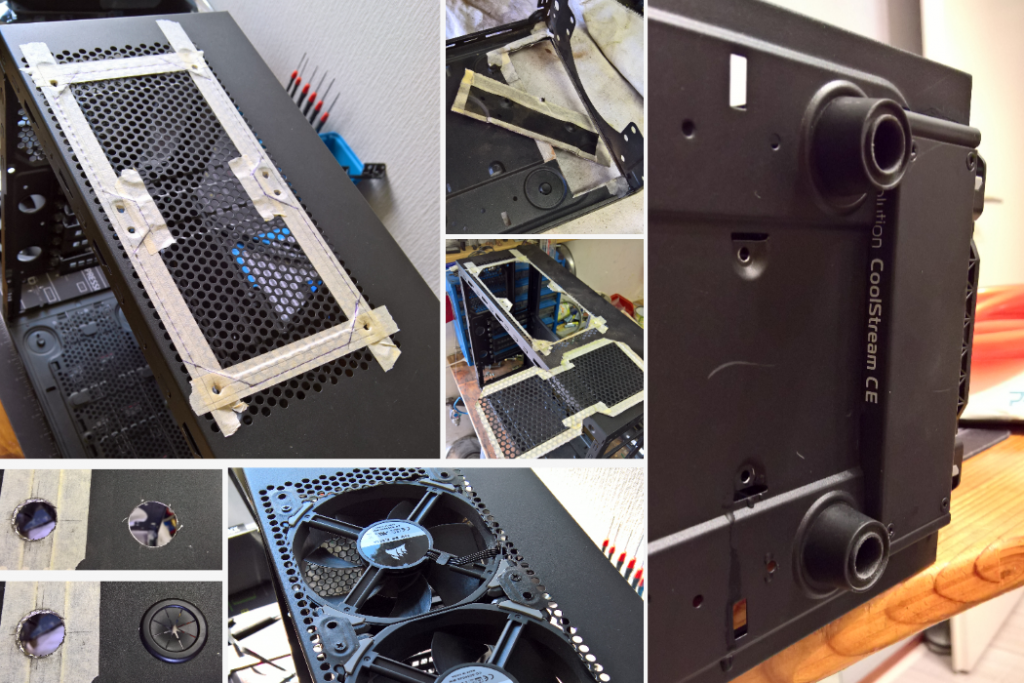

Below an example of a custom part, the wooden fan grille with dust filters.

The testing of the hardware and the early stages of the woodwork.

And the end result: